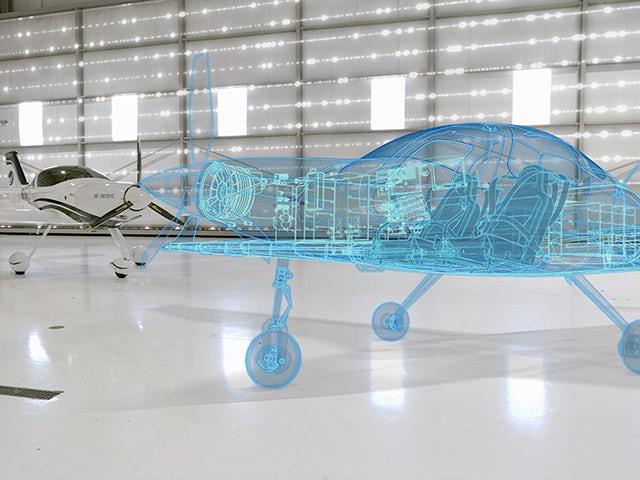

Digital Twin

We enable the most comprehensive digital twin to predict behavior, optimize performance and validate the most complex products. Learn how we bring the possibilities of tomorrow to our customers today.

Digital Twin

Zipline’s drones, designed with Siemens software, have flown thousands of missions and saves hundreds of lives—with near 100% reliability.

Tomorrow's Electric Planes, Today

This is the story of how an electric aircraft startup is achieving success through electrification and an accelerated verification process

Innovative Power

Accelerating the development of fusion energy. See how Siemens and Tokamak Energy are making it possible.

Electronics & Semiconductors

World-class electronics manufacturer ROJ Electronics Srl. finds success with Siemens Smart Manufacturing solutions, powered by digital transformation and the digital twin.