Manage multiple customers and product complexity

Digitize your operations using one software system to transform the way you make parts.

- Improve time to market by automating end-to-end processes to accelerate production

- Minimize downtime for different set up testing, validating, and commissioning product designs

- Standardize processes by re-using company data, designs, and knowledge to ensure repeatability

Measure resource utilization

Protect your heavy investment in machines, equipment and technology with maximum run time. Ensure programs are validated and verified to run efficiently with minimal interruption.

- Minimize "lights out" manufacturing

- Automate end-to-end processes to accelerate production

- Optimize investment in machines and equipment

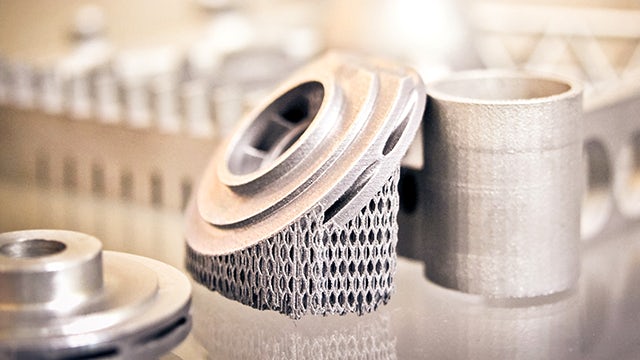

- Improve programming production processes for robotics and additive manufacturing

Consistent quality control

Effective quality management requires collaboration across all departments, including external supply chains. Tracking data from supply chain systems or external databases is needed to ensure increasing quality requirements and regulatory compliance.

- Streamline order to manufacturing controls

- Achieve regulatory compliance

- React quickly to design changes

- Compare measured data to improve quality and inefficiencies

Supply chain visibility

Visibility into your supply chain prevents surprises when a shipment is late or incorrect creating immediate adjustments to your production schedule.

- Gain real-time visibility into supply data and information

- Integrate all partners and systems easily into logistics processes

- Create better forecasts to make more reliable decisions

- Cover all steps from initial shipping request to final delivery

Boost your part manufacturing productivity

How can a comprehensive CAD/CAM software help you grow your part manufacturing business?

- Automate NC programming to save time and standardize processes

- Cut machining time by up to 60% and improve part quality using advanced toolpaths

- Simulate complete manufacturing processes to reduce set-up time and maximize machine uptime

- Digitally connect team members, equipment and processes for a seamless collaboration

Application Development

Citizen technologists - your in-house developers of varying experience levels can create multi-experience applications without writing a single line of code to address the demand for solutions across the organization.