NX

NX Mold Connect

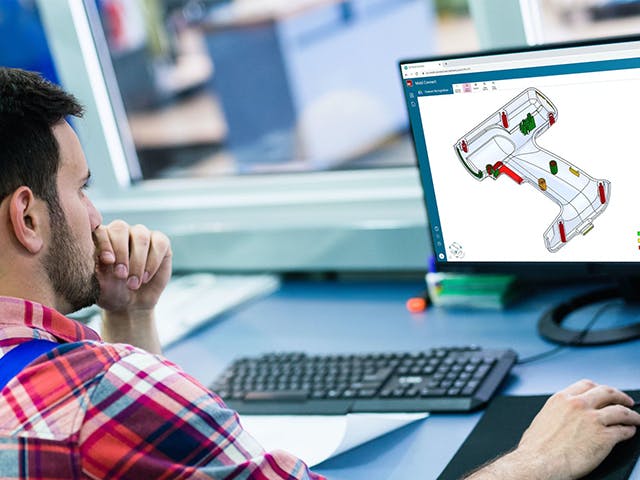

The NX Mold Connect app improves the RFQ process for OEMs and suppliers for injection molded parts through better collaboration, validation and cost estimation

Change country

Automate your injection molding process

NX Mold Connect enables tool shops to collaborate seamlessly with OEM clients in one central location on injection molded parts. With the NX Mold Connect app, tool shops are able to improve quoting and accuracy of workflows while OEMs are better able to predict their costs before RFQ submission.

Collaboration between OEM and tool shop

Share mold-making projects with users and submit requests for quote (RFQ) to multiple tool shops through the app. Allow them to view, download, or have full access to a project's files and communicate via in-app messaging for questions, recommendations or comments. This seamless process eliminates the need for other various communication efforts and manual file transfer methods, allowing users to easily view the status of their project throughout the process.

Mold part design for manufacturing

Perform mold part design validation using design for manufacturing (DFM) analysis on part geometry, wall thickness, mold filling, and part features at the click of a button. Doing this early in product development reduces the need for rework and material waste.

Final injection molded part cost estimation

Generate more accurate cost estimations faster with NX Mold Connect tool costing automation. Tool shops can enter the costs for labor, parts, and materials. The app identifies features such as ribs, undercuts, openings and more which are then included in the bill of materials. This combination of pricing and feature recognition creates an automated, accurate quote for the mold.

Interoperability with NX

Synchronize files from desktop to cloud and ensure that tool shops and OEMs are working with the most current data. Using up-to-date data for feature recognition and automated tool costing provides the most accurate estimation of injection molded part cost.

Common Injection molding process challenges

Learn how NX Mold Connect can help with:

- Difficult for OEM's to find and certify tool shops

- Difficult for OEM's to do business with many tool shops for each RFQ

- Difficult for tool shops to receive and manage RFQs from many customers

- Difficult for tool shops to validate mold part designs

- Difficult for tool shops to create accurate estimates for quotes

- Difficulty tracking and managing molded part projects