How can you improve your electric vehicle development?

Your competitive edge relies on quickly getting to market with a full line up of long-range, safe and comfortable electrical vehicles (EVs). How do you do this and deliver what your customers actually want?

Launch a product engineering environment that accelerates EV design, verification and validation. Implement a system that considers manufacturing implications upfront.

Ensure manufacturing flexibility, accuracy and quality

Accelerate electric vehicle innovation and production while meeting environmental targets and satisfying consumer demand.

Faster model development & pack validation

Use multi-physical features to run faster studies, helping you to develop models and validate pack components more efficiently. (PSA Peugeot Citroën)

Reduction in initial vehicle assessment cycle time

Create a digital thread and comprehensive digital twin for new and on-going vehicle projects to quickly develop safe and functional mobility solutions. (NEVS)

Faster NVH prediction

Increase productivity with tools to enhance your prediction capabilities for noise, vibration and harshness simulation. (Renault Green)

Shorten your development cycle

How can you bring a full range of safe, comfortable, fully featured vehicles to market faster than your competitors?

Explore the three key areas of electric vehicle design. Our solutions are developed to meet your needs in each of these areas:

了解西门子汽车电气化解决方案如何通过提供集成式虚拟环境来加快电动汽车开发,并同时整合新能源系统和复杂功能,进而实现:

- 通过持续的价值链协同以增强决策能力

- 通过尽量重用先前的设计组件以加快开发速度

- 通过基于模型的设计即正确方法以减少错误

- 通过提早与制造团队共享产品信息以实现卓越运营

通过使用电池和电动动力总成等复杂系统的多物理场模型以开发稳健的设计。通过在所有系统中进行多属性优化,以尽可能地提高续航里程、舒适度、性能和安全性。

Run more efficient vehicle electrification projects

Design iterations within an hour

Get ample time to create a mature design early in the process. (NEVS)

Reduction in project cycles

By collaborating with automakers throughout the planning, simulation and commissioning stages, project cycles can be reduced by up to 20-30%. (MINO case study)

More time for new product development

Research and testing new lines helps launch more products to the market faster. (Cabycal case study)

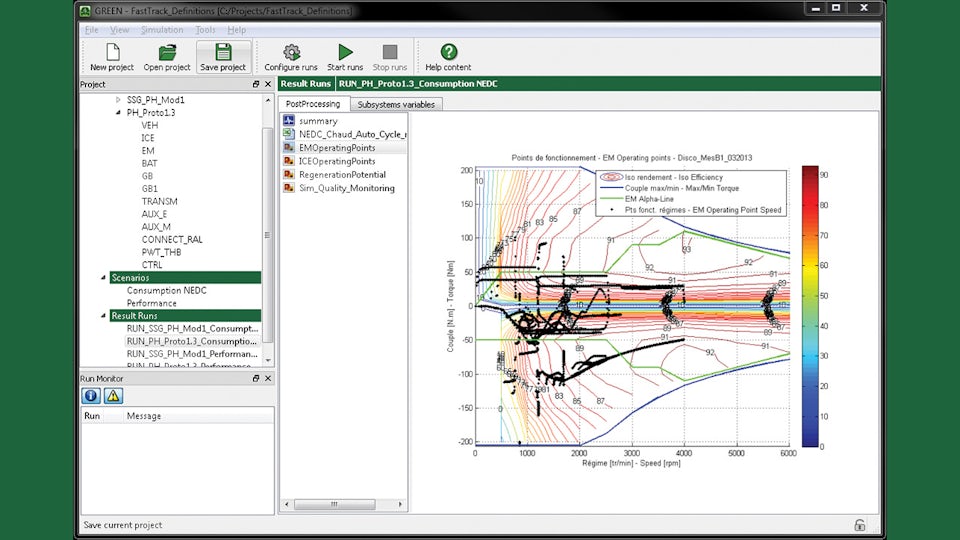

Renault (GREEN)

雷诺采用 Simcenter Amesim 简化未来混合动力车和电动车的开发工作

公司:雷诺 (GREEN)

行业:汽车及交通运输行业

位置:布洛涅-比扬古, France

Siemens 软件:Simcenter 3D Solutions, Simcenter Amesim

The GREEN platform powered by Simcenter Amesim is meant to unite different expertise domains and different systems engineers, and enables teams that never collaborated to sit together and communicate on their engineering issues to find common solutions.

Explore our resource library

How can you accelerate EV development while also introducing the models and features that will drive consumers to your brand?

Solutions to accelerate vehicle electrification

Composite product design

E/E systems development

Performance engineering

Manufacturing process planning

Application Development Platform

Frequently asked questions

The electrification of vehicles presents a host of advantages for manufacturers in the automotive industry. Embracing electric vehicle technology allows manufacturers to align with global sustainability initiatives, establishing their brand as one focused on supplying the growing demand for eco-friendly alternatives. Additionally, the simplified drivetrain of electric vehicles, with fewer moving parts, leads to streamlined production processes, reducing manufacturing complexity and potentially lowering production costs.

As governments worldwide incentivize the development and production of electric vehicles, manufacturers stand to benefit from financial incentives and tax breaks, fostering a favorable business environment. Being at the forefront of EV innovation positions manufacturers as industry leaders, opening up new markets and attracting environmentally-conscious consumers. By incorporating electrification into their portfolios, manufacturers can leverage these benefits to drive growth, enhance brand reputation, and contribute to a more sustainable automotive future.

To rapidly integrate design elements from previous platforms, utilize our comprehensive suite of design and engineering tools. Our solutions facilitate efficient collaboration, reuse of design data, and streamline the integration process. Key steps include:

- Digitalization and PLM solutions: We provide product lifecycle management (PLM) tools that enable a digital thread across the product development process. This allows for seamless integration of design elements from previous platforms, ensuring data consistency and accuracy.

- CAD software: We offer advanced computer-aided design (CAD) software, allowing engineers to efficiently model and modify components. Utilizing parametric design features and standardized libraries helps accelerate the integration of proven design elements.

- Simulation and validation tools: We offer simulation and validation tools to assess the performance of integrated design elements. This ensures that modifications align with performance requirements and regulatory standards, reducing the risk of errors.

- Collaboration platforms: We emphasize collaboration tools that facilitate communication among cross-functional teams. This promotes a collaborative environment, enabling rapid decision making and problem solving during the integration process.

- Knowledge reuse: We advocate for knowledge reuse through digitalization. By capturing and documenting design and engineering knowledge, teams can leverage proven solutions from previous platforms, saving time and resources.

Meeting strict environmental targets while satisfying consumer demand in the EV industry requires a strategic approach that balances sustainability with consumer expectations. We help you address this challenge through:

- Comprehensive electrification solutions: We offer a holistic suite of electrification solutions, covering everything from efficient energy storage systems to smart charging infrastructure. This ensures that the entire EV ecosystem aligns with environmental goals while meeting the growing demand for electric mobility.

- Collaboration for sustainability: We collaborate with automotive manufacturers to integrate eco-friendly practices into the entire supply chain. This involves working closely with suppliers to ensure sustainable sourcing of materials and promoting environmentally conscious manufacturing processes.

- Customization for consumer preferences: We recognize the importance of consumer satisfaction and tailor electrification solutions to meet diverse consumer preferences. This includes developing electric vehicles with extended range, fast-charging capabilities and advanced features, aligning with what modern consumers seek in their vehicles.

- Data-driven decision-making: We employ data-driven analytics to understand market trends and consumer behavior. This helps manufacturers make informed decisions on product development, ensuring that environmentally friendly features are aligned with consumer demands.

The EV industry faces several challenges in development, ranging from battery technology limitations to charging infrastructure.

- We support electric vehicle manufacturers in optimizing their production processes through advanced automation and digitalization solutions. This helps streamline manufacturing, improve efficiency and reduce costs in the production of electric vehicles.

- Another major obstacle is the development of efficient and cost-effective batteries with extended range and lifespan. We offer cutting-edge battery technologies and systems that enhance the performance and longevity of electric vehicles.

- Charging infrastructure is another challenge, with the need for widespread and fast-charging networks. We address this by providing smart and scalable charging solutions, contributing to the expansion of reliable charging infrastructure globally.

- Siemens supports electric vehicle manufacturers in optimizing their production processes through advanced automation and digitalization solutions. This helps streamline manufacturing, improve efficiency and reduce costs in the production of electric vehicles.

- In the realm of electric mobility, we serve as a strategic partner, offering a comprehensive suite of solutions to tackle challenges in battery technology, charging infrastructure and manufacturing processes. By leveraging Siemens' expertise, electric vehicle developers can navigate the complexities of the industry and accelerate the transition to a sustainable and efficient electric transportation ecosystem.

Learn more

Watch

Video | Electrify the future of automotive with Siemens vehicle electrification

Video | Collaborative virtual development environment

Video | Comprehensive design and optimization simulation

Listen

Podcast | Digitalization and the future of vehicle performance engineering

Podcast | Navigating sustainability in the automotive industry

Read

White paper | Transforming manufacturing planning in the EV era

Ebook | Accelerate EV development with design and simulation

White paper | Transforming the future of automotive with a solution for E/E systems development