In che modo una soluzione PLM sul cloud può aiutarti a fornire prodotti innovativi e di alta qualità, mantenendo i costi ragionevoli e garantendo un rapido ritorno sull’investimento?

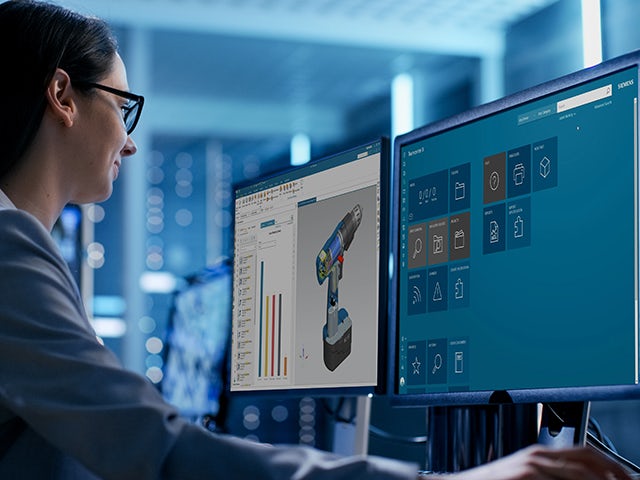

Implementa una soluzione PLM per creare un sistema di dati e collaborazione che consenta all’intera azienda di lavorare come un unico team, in tempo reale, con un’unica fonte di verità: dalla progettazione alla prototipazione, dai test alla produzione e oltre.