コストを妥当に保ち、迅速な投資回収を確保しながら、革新的で高品質な製品を提供するために、クラウド上のPLMがどのように役立つでしょうか?

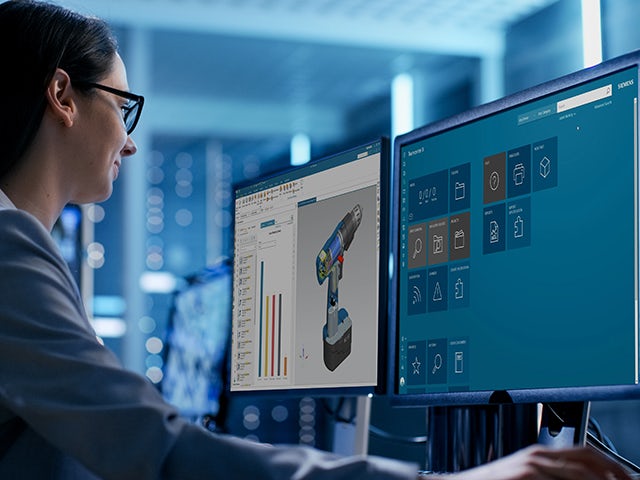

PLMソリューションを導入してデータとコラボレーションのシステムを構築することで、信頼できる唯一の情報源を利用して、設計からプロトタイピング、テスト、製造まで、組織全体が1つのチームとしてリアルタイムで作業することができます。

顧客は、高品質で生産され、市場投入までの時間が短い、革新的で持続可能な製品を求めています。さまざまな複雑なプロセスを円滑に進めながら、一流の製品を迅速に開発して提供するにはどうすればよいでしょうか?

製品ライフサイクル管理 (PLM) ソフトウェアを使用して、チーム、データ、プロセスをつなぐことで、簡単、迅速、大規模に複雑な製品開発に取り組むことができます。

Lifecycle Insightsの調査結果:

59%の企業が、製品開発の複雑化が進んでいると報告しています。

53%の企業が、目標要件を満たすことを主な課題として挙げています。

46%の企業が、着手や納期を守れている製品開発プロジェクトは、10件のうち6件未満だと答えています。

コストを妥当に保ち、迅速な投資回収を確保しながら、革新的で高品質な製品を提供するために、クラウド上のPLMがどのように役立つでしょうか?

PLMソリューションを導入してデータとコラボレーションのシステムを構築することで、信頼できる唯一の情報源を利用して、設計からプロトタイピング、テスト、製造まで、組織全体が1つのチームとしてリアルタイムで作業することができます。

PLMは情報管理システムです。PLMは、製品ライフサイクル全体を通じて、データ、プロセス、ビジネスシステムを統合します。

PLMソフトウェアを使用して、より多くの情報に基づいた意思決定を行うことで、市場投入までの時間を短縮し、品質と持続可能性を向上し、効率を高め、コストを削減できます。

製品とプロセスに関連するすべての情報をまとめることで、ナレッジが複数の異なるシステムやデータベースに保存され、サイロ化されることがなくなります。

ビジネスのすべての関係者は、製品データを効果的に検索、共有、再利用したり、プロセスを同期、自動化することができます。

システムとサブシステムを統合して、コストがかかる最終段階での問題を回避し、最初から正確な製品定義を作成できます。

ドメインやチーム間のコラボレーションを可能にし、複雑さを克服し、よりスマートな製品意思決定を行い、製品イノベーションを加速することができます。

製品要件を把握して伝達できます。部門間での共同設計が可能です。製品ライフサイクルをつなぐデジタル・バックボーンの単一の部品表 (BOM) を作成できます。製品の変更に迅速に対応できます。

以下のソリューションから始める、またはすべてのTeamcenterソリューションをご覧ください。

今すぐTeamcenter Xを体験できます。サービスとしてのソフトウェア (SaaS) PLMのパワーをお試しください。CAD、変更管理、BOM管理などの最も一般的なユースケースをサポートし、業界に合わせて事前構成されたソリューションをご覧ください。

Teamcenterは、Forrester Researchによって「PLMのリーダー」に選ばれました。

ディスクリート・メーカー向けPLM製品の評価をまとめた同社の報告書「The Forrester Wave™: Product Lifecycle Management for Discrete Manufacturers」 (2023年第一四半期) にて、シーメンスのTeamcenterは、評価に参加したほかのどのベンダーよりも多くのカテゴリーで、最高の得点を獲得しました。

G2の顧客レビューで、Teamcenterは「あらゆる規模の企業に最適なPLMソフトウェアである」と評価されました。詳細については、PLMソフトウェアの比較表をご覧ください。

Teamcenter Xなどのクラウド・ネイティブ・ソリューションを使用すれば、管理のオーバーヘッドを最小限に抑えながら、設計、エンジニアリング、製造、イノベーションに100%集中することができます。

製品ライフサイクル管理の取り組みを簡単に開始できます。当社は、サポートとサービスで導入を支援します。

Teamcenterをクラウドで導入するには、任意のプロバイダーを利用するか、シーメンスのSaaSを利用するかを選択できます。または、オンプレミス版を導入して、社内ITチームで管理することもできます。Teamcenterは単なる大規模エンタープライズ・ソリューションではありません。

Teamcenterを導入し、その機能を簡単に習得できます。オンデマンド・トレーニングのほか、講師によるトレーニングを用意しています。

コミュニティに参加して、Teamcenterの専門家に質問してみましょう。

PLMソフトウェアは、データ、人、プロセス、多様なソフトウェア・アプリケーションを統合します。サイロ化され、分断されたシステムをつなぎ、信頼できる唯一の情報源として機能します。PLMソフトウェアを使用すると、製品ライフサイクル全体を通じて、効率的かつコスト効率の高い方法で情報を管理できます。

PLMソフトウェアは、製造会社がコンセプトから生産までイノベーションを加速できるようサポートします。多くの製造会社では、製品とプロセスのナレッジが複数のシステム、データベース、パソコンに分散しています。安全でアクセスしやすいPLMシステムは、多様なチームが複数のアプリケーションから使用できるため、誰でも最新のデータにアクセスできます。

ディスクリート型製造業やプロセス型製造でも、厳格な規制基準に準拠した、持続可能で高品質の製品に対する顧客の要求により、製品開発の複雑化が進んでいます。

包括的なPLMソリューションのみが、チーム、データ、プロセスを統合して製品開発を合理化し、これらの複雑さを管理し、対処できます。

PLMソリューションは、あらゆる組織に信頼できる唯一の情報源を提供し、単一の正確な製品定義を保証することで、コラボレーションの強化、市場投入までの時間の短縮、コスト削減、品質管理の向上を実現します。PLMソリューションを導入することで、部門や分野を超えたイノベーションをより迅速かつ大規模に加速することができます。

Teamcenterは、シーメンスが開発したソフトウェア・プラットフォームで、ディスクリートおよびプロセス産業の企業が、初期設計から生産、メンテナンスまで、製品のあらゆる側面を効率的に管理できるようサポートします。製品関連情報を整理、共有する中央ハブとして機能し、チームが正確な最新データを使用して作業できるようにします。

また、Teamcenterは、さまざまな部門やサプライヤー間のコラボレーションをサポートし、ワークフローを合理化し、企業が品質基準や規制要件を順守できるようサポートします。基本的には、製品の開発・メンテナンスの複雑なプロセスを整理して効率的にするツールです。

Teamcenter PLMソフトウェアは、製品エンジニアリング・プロセスを最適化します。さまざまな業界での製品開発を合理化し、市場投入までの時間を短縮し、製品の品質とコンプライアンスを確保します。Teamcenterの主な機能を以下に示します。

PLMツールは、プロセスを標準化、自動化してターンアラウンドを短縮することで、製品設計を合理化します。PLMソリューションを使用することで、以前の構成と部品表 (BOM) を合理化、再利用し、複数の注文を同時に管理することができます。製品定義書からCADモデルまでのトレーサビリティが向上し、顧客の変更を実装するプロセスがスピードアップし、エンジニアリングの修正が削減されます。