云端 PLM 如何帮助您交付创新、高质量的产品,同时维持合理的成本并确保快速获得投资回报?

实施 PLM 解决方案以构建数据和协作系统,推动整个组织机构以团队形式通过单一事实来源实时分工合作,涵盖从设计、原型设计、测试到制造等部门。

客户当下最迫切的需求是生产优质、创新和可持续的产品并快速上市。如何快速开发和交付一流的产品,同时顺利应对一系列复杂的流程?

使用产品生命周期管理 (PLM) 软件连接团队、数据和流程,更轻松、更快速应对复杂的产品开发流程难题,同时提高开发规模。

据 Lifecycle Insights 报告:

59% 的公司表示产品开发越来越复杂。

53% 的公司认为满足目标需求是首要问题。

46% 的公司注意到,他们仅有不到六成的产品开发项目能够如期发布或交付。

云端 PLM 如何帮助您交付创新、高质量的产品,同时维持合理的成本并确保快速获得投资回报?

实施 PLM 解决方案以构建数据和协作系统,推动整个组织机构以团队形式通过单一事实来源实时分工合作,涵盖从设计、原型设计、测试到制造等部门。

PLM 是一种信息管理系统。它在整个产品生命周期中集成了数据、流程和业务系统。

借助 PLM 软件,您可以做出更明智的决策,从而缩短上市时间、提高质量和可持续性、提高效率并降低成本。

将所有与产品和流程相关的信息汇集在一起,避免知识孤立在多个系统和数据库中。

帮助企业中的每个利益相关者更有效地查找、共享和重用产品数据,以及同步和自动化流程。

集成系统和子系统,消除昂贵的开发后期问题,并在第一时间创建准确的产品定义。

支持跨领域和跨团队的协作,帮助企业化解复杂性难题,做出更明智的产品决策并加速产品创新。

收集并传达产品需求。跨部门进行设计合作。为连接产品生命周期的数字主干创建单个物料清单 (BOM)。快速响应产品变更。

开始使用以下解决方案或浏览所有 Teamcenter 解决方案。

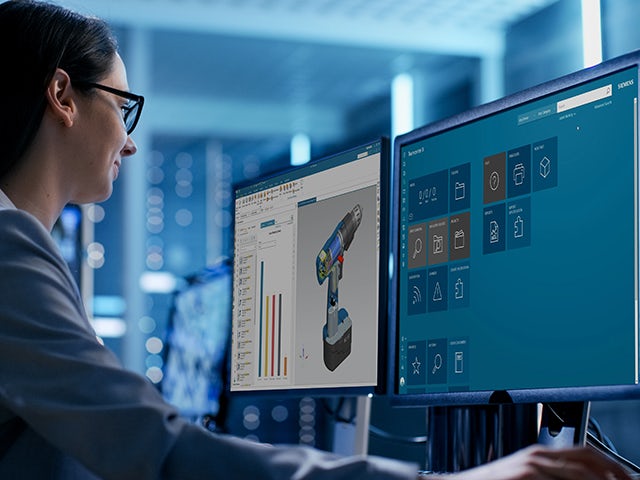

立即试用 Teamcenter X,探索软件即服务 PLM 的强大功能。探索最常见的用例,例如 CAD、变更和物料清单管理,以及预配置的行业解决方案。

Teamcenter 被 Forrester Research 评为 PLM 领域的佼佼者。

在《Forrester Wave™:2023 年第一季度面向离散制造商的产品生命周期管理》报告中,Teamcenter 在多项标准中揽获高分,遥遥领先其他参与评比的友商产品。

根据客户评价,G2 将 Teamcenter 评为适合任何规模公司的优秀 PLM 软件。查看 PLM 软件比较网格图以了解更多信息。

Teamcenter X 等云原生解决方案尽可能地降低了管理开支,使我们能够 100% 专注于设计、工程、制造和创新。

轻松开启您的产品生命周期管理之旅。我们的支持和服务将指引您一路前行。

自由实施云端 Teamcenter——可借助您选择的提供商,或西门子的 SaaS 产品。或者在本地部署,与您的 IT 团队一起管理。它不仅仅是一个大型企业解决方案。

采用 Teamcenter,轻松掌握其要素。获取点播式与指导式培训。

加入对话并获取 Teamcenter 专家对您问题的解答。

无论您是从事离散制造还是流程制造,产品开发的复杂性都在增加,因为客户需求的是符合严格监管标准的可持续、优质产品。

只有全面的 PLM 解决方案才能整合您的团队、数据和流程,从而简化产品开发,帮助您解决和攻克这些复杂难题。

PLM 解决方案可成为企业的单一事实来源,通过单一、准确的产品定义增强团队之间的协作、缩短产品上市时间、节省成本并改善质量控制。借助 PLM 解决方案,您可以大规模地加速跨部门和学科的创新。

Teamcenter 是西门子开发的软件平台,可帮助离散制造和流程制造企业有效地管理其产品从初始设计到生产和维护的方方面面。它是整理和共享产品相关信息的中心枢纽,确保团队使用准确和最新的数据。

Teamcenter 还支持不同部门和供应商之间的协作,简化工作流程,并帮助公司遵守质量标准和法规要求。从本质上来看,它是一种工具,让创建和维护产品的复杂过程变得更有条理和高效。

Teamcenter PLM 软件优化了产品工程流程。它简化了产品开发,缩短了上市时间,并确保了产品符合各个行业的质量和法规要求。Teamcenter 主要功能包括: