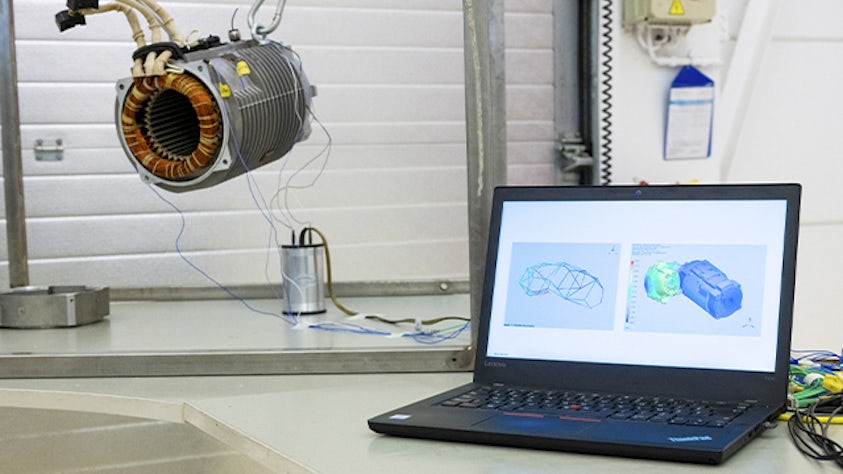

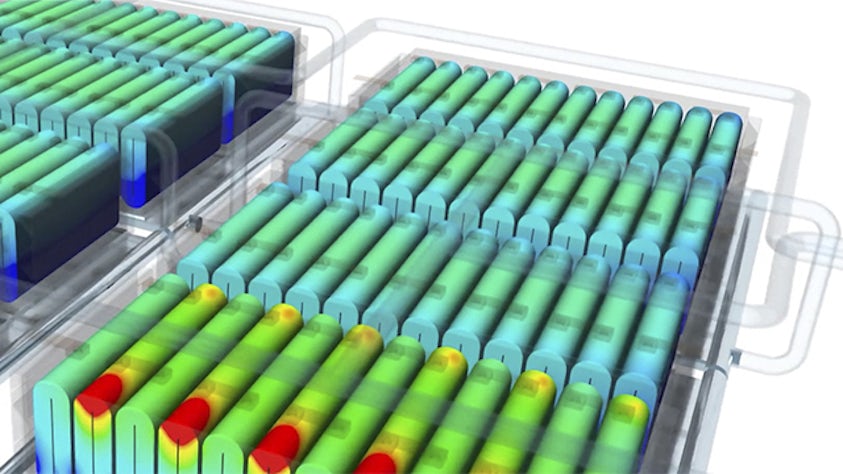

Engineering departments in all industries are challenged with the increased complexity of smart, sustainable products that today’s market demands. Simcenter Engineering and Consulting Services helps you build a digital twin of your products to make them more efficient, comfortable, reliable, and durable than ever before. We are a trusted partner at every step of your digitalization journey, from the early design stage onwards.

Our team offers services that go beyond standalone simulation efforts or isolated testing campaigns. We combine these into one comprehensive solution to help you build the true digital twin.

Related resources

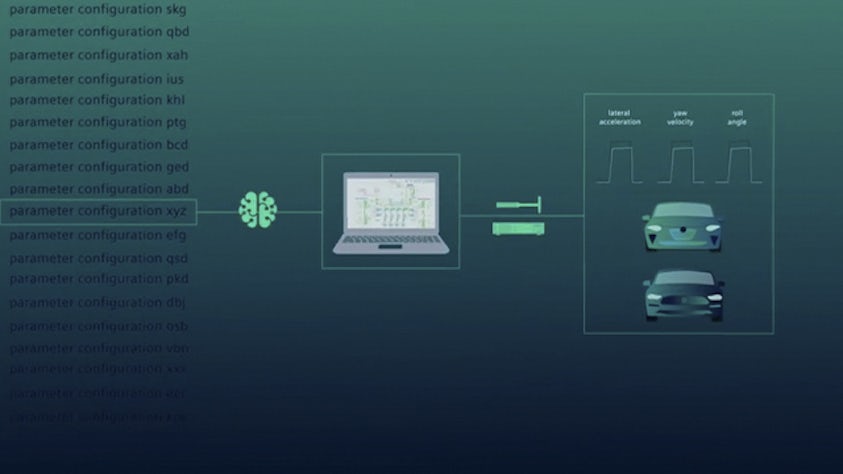

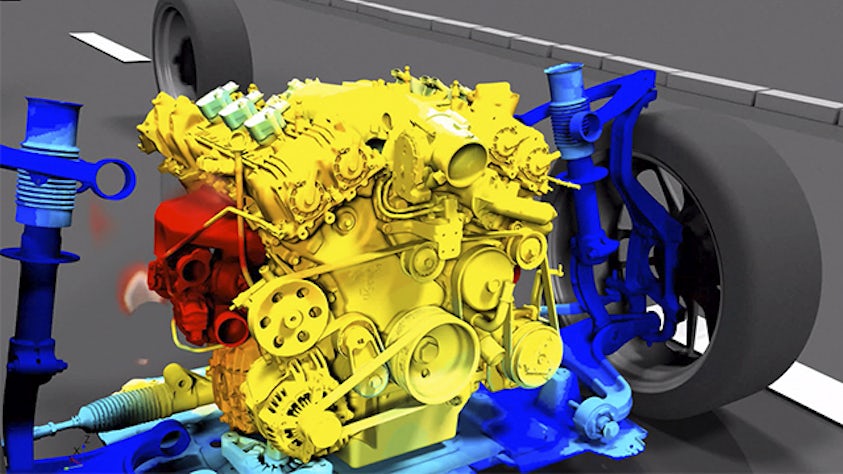

Video: The power of a multi-purpose digital twin for vehicle dynamics and beyond

Video: The executable Digital Twin (xDT)

Case study: Hyundai uses model-based systems engineering to take a new approach to virtual NVH development

Blog: How to use AI to reduce the Parameter ID process from weeks to minutes