数字孪生是实际物体、系统或工艺的虚拟表示或数字对应物。它是使用实时数据、仿真和建模技术创建的,可反映其物理对应物的行为、特征和性能。数字孪生被用于各个行业,包括制造业、医疗保健、运输和能源,以优化性能、监控运营并促进决策。

相关产品:NX CAD | Simcenter 仿真软件 | Solid Edge

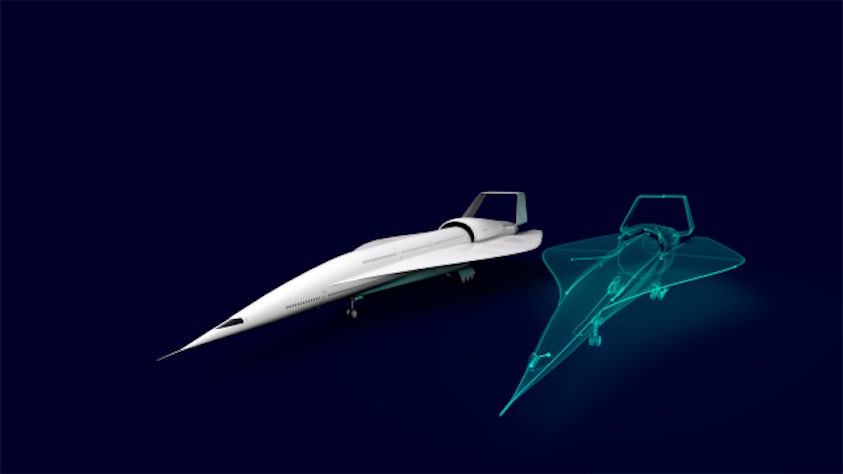

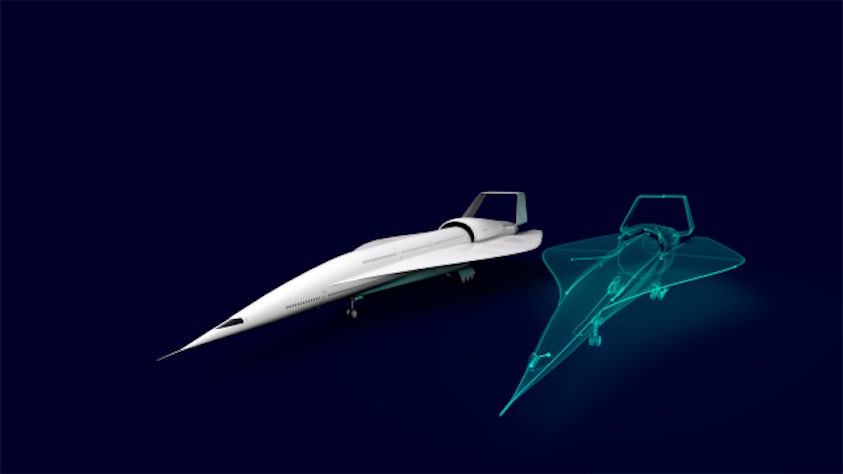

数字孪生是实际产品或流程的虚拟表示,用于理解和预测对应物的性能特点。在投资物理原型之前,可以使用数字孪生对产品和生产系统进行仿真、预测和优化。

数字孪生是实际物体、系统或工艺的虚拟表示或数字对应物。它是使用实时数据、仿真和建模技术创建的,可反映其物理对应物的行为、特征和性能。数字孪生被用于各个行业,包括制造业、医疗保健、运输和能源,以优化性能、监控运营并促进决策。

相关产品:NX CAD | Simcenter 仿真软件 | Solid Edge

通过弥合物理世界和数字世界之间的差距,数字孪生提供了一个强大的框架,可帮助各行各业的企业获取见解、优化性能和推动创新。

Product lifecycle management - Design and deliver advanced products that surpass expectations. Empower cross-functional teams with precise data using our flexible, scalable PLM tools built for industrial innovation.

Performance engineering - Boost product performance early with multiphysics simulation and testing. Improve efficiency and spark innovation across development.

Comprehensive automated design - Streamline workflows, cut development costs and support sustainable innovation with scalable solutions built for engineering teams.

Low-code application development - Build custom engineering apps up to 10x faster with fewer resources. Speed up innovation and unlock more value from core systems with scalable, flexible solutions for any size business.

Machine automation engineering - Enhance your operations to build and deliver next-gen production machines and services fast and at scale.

E/E systems development - Simplify and speed up complex E/E systems development. Explore, simulate and refine new concepts to drive innovation and deliver more value from your engineering efforts.

数字孪生通过结合多物理场仿真、数据分析和机器学习来展示设计变更、使用场景、环境条件和其他变量的影响,从而消除了对物理原型的需求,缩短了开发时间并提高了质量。

数字孪生使用来自传感器、物联网设备和其他来源的实时数据不断更新,因而在任何给定时间都能提供物理资产或系统的准确表示。

数字孪生通常结合仿真和建模技术来模拟物理资产或系统在不同条件下的行为和性能。这样可以进行预测分析、优化和情景规划。

数字孪生支持虚拟模型与其物理模型之间的双向通信。这意味着来自数字孪生的数据和见解可以为物理世界中的决策和行动提供信息,反之亦然。

数字孪生允许从虚拟环境中对物理资产或系统进行实时监控。这使得远程监控、诊断和预测性维护成为可能,可以优化性能并减少停机时间。

The digital twin in engineering enables comprehensive system modeling and simulation before physical production begins. It combines Model-Based Systems Engineering (MBSE) with detailed design capabilities to create virtual representations of products, allowing engineers to validate requirements, optimize designs and predict performance in the digital world before building in the real world. This approach helps identify potential issues early in the development process, reducing costly late-stage changes and ensuring design requirements are met.

Model-based systems engineering (MBSE)

Digital twins in manufacturing create virtual replicas of production processes, equipment and entire factory operations. A digital twin can use closed-loop feedback to enable real-time monitoring, optimization of production workflows and validation of new or updated manufacturing processes before implementation. By simulating production scenarios, manufacturers can identify bottlenecks, optimize machine utilization, use predictive maintenance to minimize downtime and ensure efficient production planning while reducing commissioning time.

A digital twin of lifecycle management provides a continuous, traceable record of product development and performance from idea to innovation and product use. This integrated approach ensures that all stakeholders have access to a single source of truth, enabling better, faster decision-making and more efficient change management by breaking down silos across different departments and disciplines. This allows stakeholders to operate concurrently while maintaining a centralized connection between requirements, design decisions and product performance throughout the entire product lifecycle.

Integrated lifecycle management

The service digital twin supports post-delivery product maintenance, updates and optimization by providing accurate, up-to-date product information to service teams. It enables predictive maintenance strategies, remote diagnostics, software upgrades and efficient service planning by maintaining a virtual representation of the deployed product. This approach helps optimize spare parts management, reduce service costs and improve product uptime, ensuring the product maintains performance standards and meets customer’s expectations.