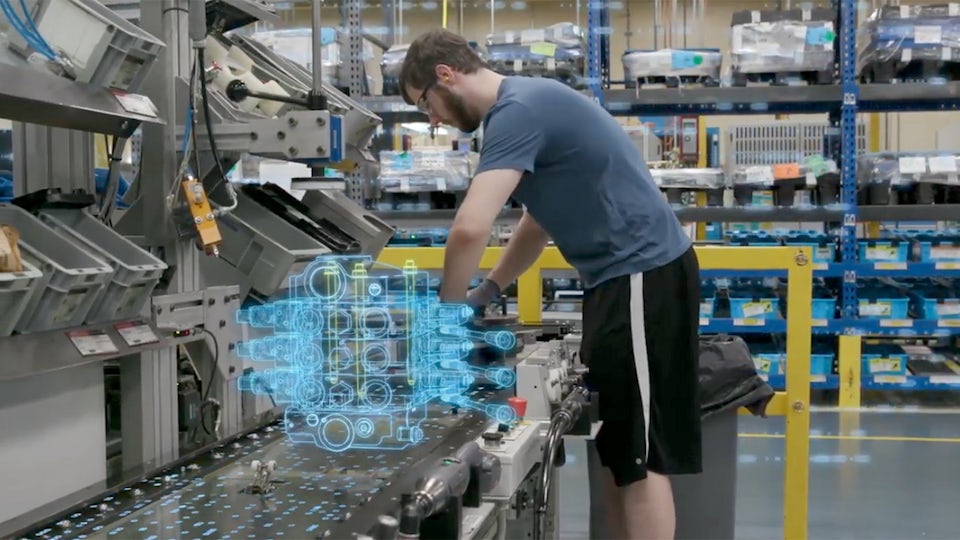

Improve efficiency in a smart factory environment

Staying ahead in today's component manufacturing market requires agility and innovation. Unlock an efficient, flexibile and more productive intelligent factory with a comprehensive smart manufacturing solution. Discover how digital tools save planning time and resources, uncover new operational efficiencies and streamline quality processes.

Embrace the future with smart manufacturing

Smart, connected factories leverage digital tools to plan more agile production lines, achieve greater efficiency and drive continuous improvement.

Increase in throughput

Get more from production lines with simulation tools. Rapidly test multiple variations and scenarios to achieve optimal machine design and line layout. (Zahoransky)

Shorter production time

Increase productivity and streamline shop floor operations with an improved scheduling process that finds and eliminates bottlenecks. (Rotis)

Duplicate data entries

Achieve improved transparency throughout the manufacturing process and build upon high quality standards while keeping administrative costs low. (Liebherr)

Industrial machinery manufacturing solutions achieve:

Higher production efficiency

Simulate an existing production line with cycling processes and batch processes, and use the data to minimize downtime and maximize output. (HCM)

Faster root cause identification time

Integrate data collection into production machines to reduce the time it takes to find a defect from a few weeks to a few hours. (Meccanotecnica Umbra)

Shorter on-site commissioning time

Accelerate time-to-delivery with virtual commissioning. Virtual commissioning also improves performance, mitigates risks and cuts rework in half. (Wipro PARI)

Danfoss

Danfoss' digital journey and strategic approach to MES.

Danfossのデジタル化への取り組みと、MESへの戦略的アプローチ

会社:Danfoss

業界:産業機械

開催場所:ノードボーグ, Denmark

シーメンスデジタルインダストリーズソフトウェア:Opcenter Execution Foundation

[Siemens' MES] supports us, [helping] spread process improvements and eliminate legacy tools. The dual benefit helps improve product quality and process efficiency, while also reducing operational risk and setting the stage for future shared improvements.

Explore our resource library

Make the smart factory of the future a reality. Use digital planning tools to design and implement smart and agile production lines and machine shops. Realize better process flexibility and greater capacity using customizable MES solutions. And continuously drive efficiency and improve quality with closed-loop manufacturing.

Deliver high-quality products with our solutions

Manufacturing process planning

Manufacturing execution management

Quality management

Line automation engineering

エッジ、IoT、ライフサイクル解析

ローコード・アプリケーション開発

Frequently asked questions

Industrial machinery manufacturing is the process of creating machines, equipment or parts, typically for use in commercial manufacturing settings; for example, creating a machine that can produce soda bottles.

To achieve operational efficiency in manufacturing, businesses should embrace digital tools that augment manufacturing planning, execution, and optimization. A smart manufacturing solution provides the foundation for improving the factory environment.

Businesses can reduce production costs through several means: a digital twin can plan for specific expenditures; an integrated MES-PLM system can circumvent expensive bottlenecks, and closed-loop data tools can suggest cost-reducing improvements.

To improve production line efficiency, an agile MES is key. A flexible MES makes it possible to align on requirements, regulations, and quality, in turn optimizing factory-wide processes and making it easier to execute quickly on the shop floor.

Closed-loop tools are fundamental to improving product quality. Closed-loop tools capture global machine and factory data via edge-sharing devices and the Internet of Things; AI and ML then decode this data, suggesting quality and performance improvements.

By securely integrating your IT and OT systems, you'll gain valuable insights into machines and parts across every production site. In turn, you can act on this data, implementing improvements that reduce worldwide quality issues in manufacturing.

Learn more

Watch

Video | Personalize your MES with low-code

Video | A digital approach to manufacturing for industrial machinery

Video | Closed-loop quality management for industrial machinery